-

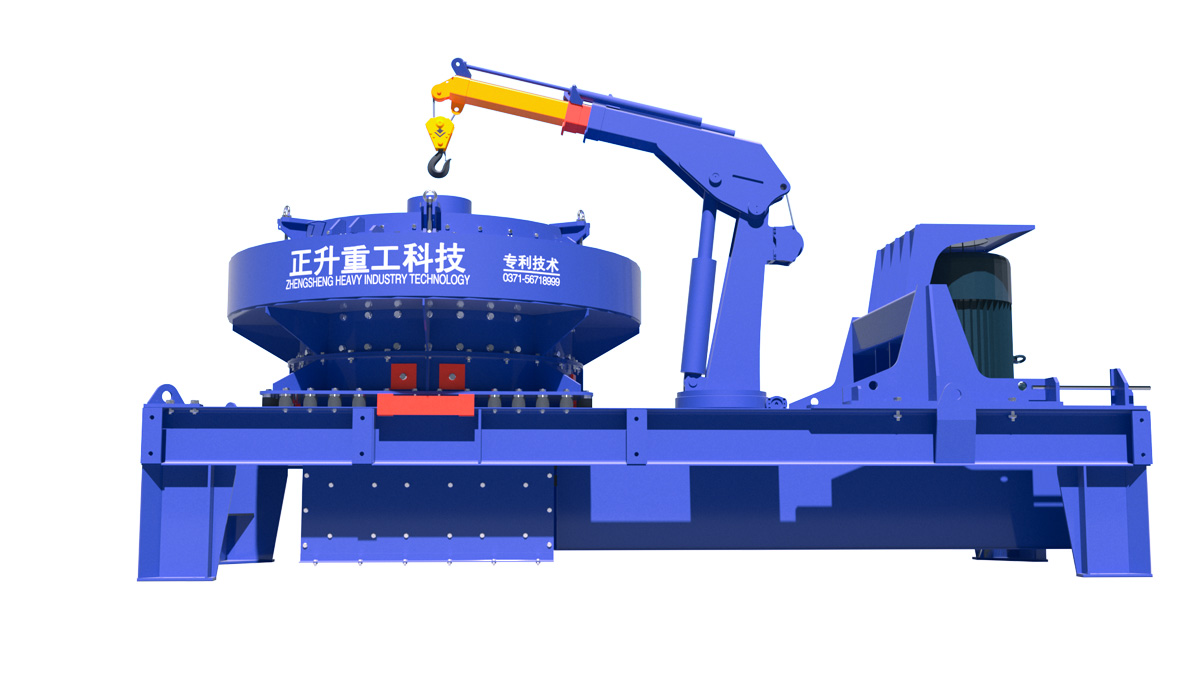

Subvert Tradition :ZSDI Sand Making Rotor Centrifugal Crusher

-450KW Power , Output : 200 Ton/H Sand

-Six cavity structure, Non clogging production

-Mechanical boom:Maintenance is more time-saving and simple

-Energy consumption dropping 28.57% then Traditional VSI impact Crusher

-Super large feed particle size :80MM (plus 30mm than Traditional VSI)

-Shaping and sand making integrated machine

-Thin oil lubrication, various automatic protection measures to reduce fault shutdown time

- Remote visual monitoring, intelligent control

explore

-

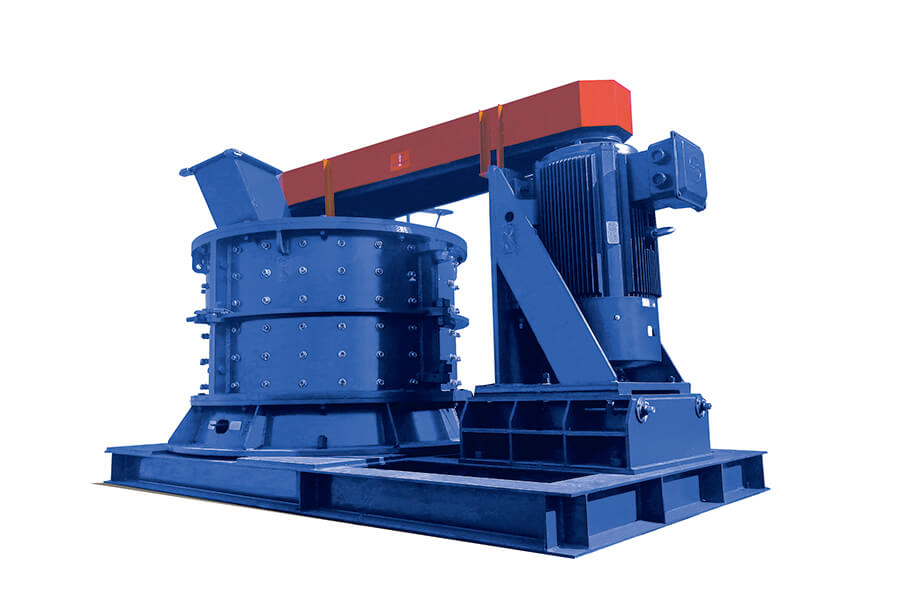

ZS high efficiency centrifugal impactive sand making machine

● Energy consumption dropping 36.5%

● 20,148,000 kwh of electricity can be saved per year

● More than double feed particle size compared with traditional VSI

● More than double sand forming rate compared with traditional VSI

● Highly automatic and intelligent

● Shaping and sand making integrated machine

● Double cavity structure, non clogging production

● Thin oil lubrication, various automatic protection measures to reduce fault shutdown time

explore

-

ZSL Series Compound sand making machine

● If your raw material is all soft rock, choose it

● Using the principle of stone striking stone, the wear is small and the service life of vulnerable parts is long

● BIGGER INPUT SIZE ≦ 100-240MM

● After crushing, 70 – 85% of the materials below 3mm can be reached

● Applicable to small and medium-sized investors

● Stable rotation, low noise, low vibration and good sealing. The utility model has the advantages of convenient operation, small floor area, convenient installation and maintenance.

explore

-

HZSL High efficiency Eco environmental protection sand making plant

● The content of stone powder can be controlled intelligently

● The fineness modulus is stable and adjustable between 2.2-3.0

● Dust zero emissions, low noise, no vibration

● The particle size distribution is uniform, and the grading is continuous and stable

● The particle shape is cubic polyhedron, which is comparable to natural sand. Its bite property is good, which can effectively improve the strength and durability of concrete and the pumping capacity of concrete

● Low energy consumption

● As its linear gradation, it can save 30-70kg cement per cubic meter of C30 compared with natural river sand

● It adopts fully enclosed conveying, production and negative pressure dust removal design, and the emission standard fully meets the national environmental protection requirements

explore

Contact Us Now

Submitting your email address can ensure that you receive our latest consultation as soon as possible!

Inquiry now

*We will not share your personal information

Inquiry now

*We will not share your personal information