Subvert Tradition :ZSDI Sand Making Rotor Centrifugal Crusher

Video

Video

R & D background

R & D background

In recent years, the sand and gravel aggregate industry is constantly developing and changing. Due to ecological protection, machine-made sand has gradually replaced the original natural river sand. In order to actively respond to the general trend of energy conservation and carbon reduction in the world, under the background of the original production experience of sand making machine and always adhering to innovation to meet the market demand, our company has continuously absorbed advanced ideas and combined with user experience feedback to iteratively develop a new generation of sand making machine ZSDI Sand Making Rotor Centrifugal Crusher.

Working principle

Working principle

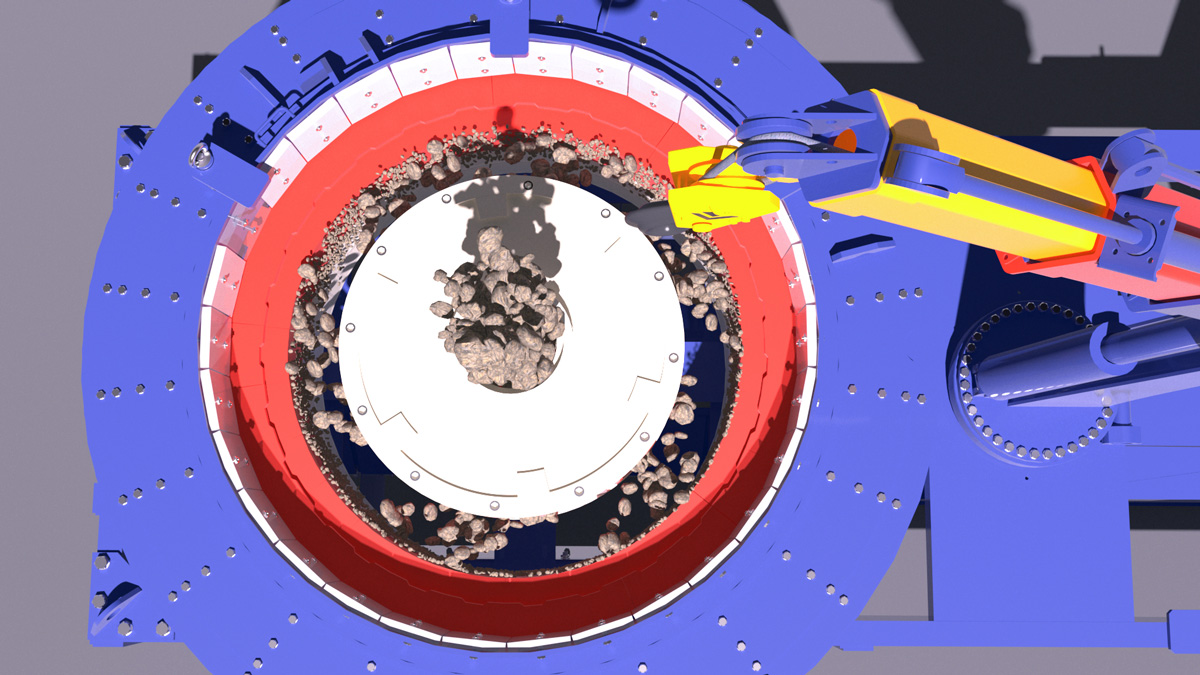

The material directly enters the rotating rotor cavity through the feed pipe and is thrown out through the throwing port under the action of centrifugal acceleration force. The material strikes the crushing wall (annular lining plate or stone layer sand bed) of the machine body at a specific speed and direction to form crushing. At the same time, the rebounded material collides and rubs to form a circular blow. With the crushing process, small particles gradually form a material layer curtain near the peripheral guard plate, so as to improve the crushing effect and protect the equipment. Fine machine-made sand is discharged from the discharge port at the lower end.

Equipment Character

Equipment Character

1.Robust performance:Output 200 Ton/H Sand only 450KW Power

1.Robust performance:

Output 200 Ton/H Sand only 450KW Power

The machine only needs a 450KW motor to drive, which can realize 200tph. Compared with the 630kw sand making machine in the market, it can save 180 ° electricity per hour. Remarkable energy saving effect.

2.Six cavity structure:Non clogging production

2.Six cavity structure:

Non clogging production

Subvert the traditional 6-cavity design. In the central feeding mode, tell the rotating rotor to fill the crushing cavity instantly, increase the collision and crushing probability between materials, weaken the wear of materials on vulnerable parts, and prolong the service life of the equipment while optimizing the particle shape of finished products

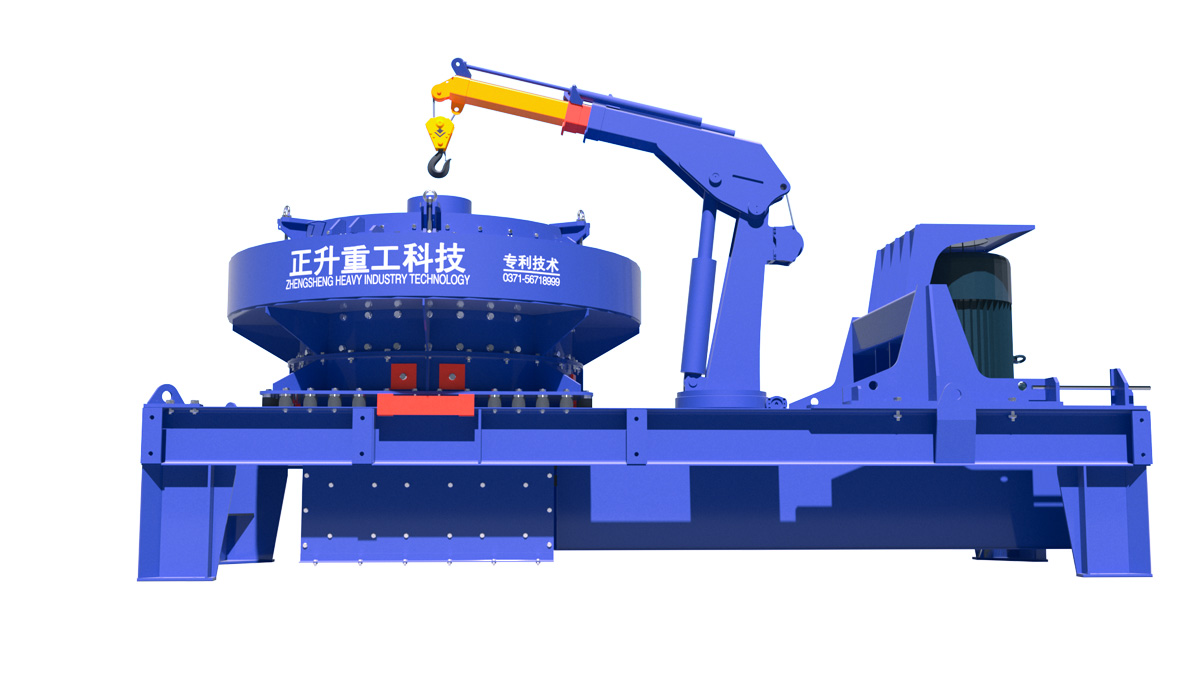

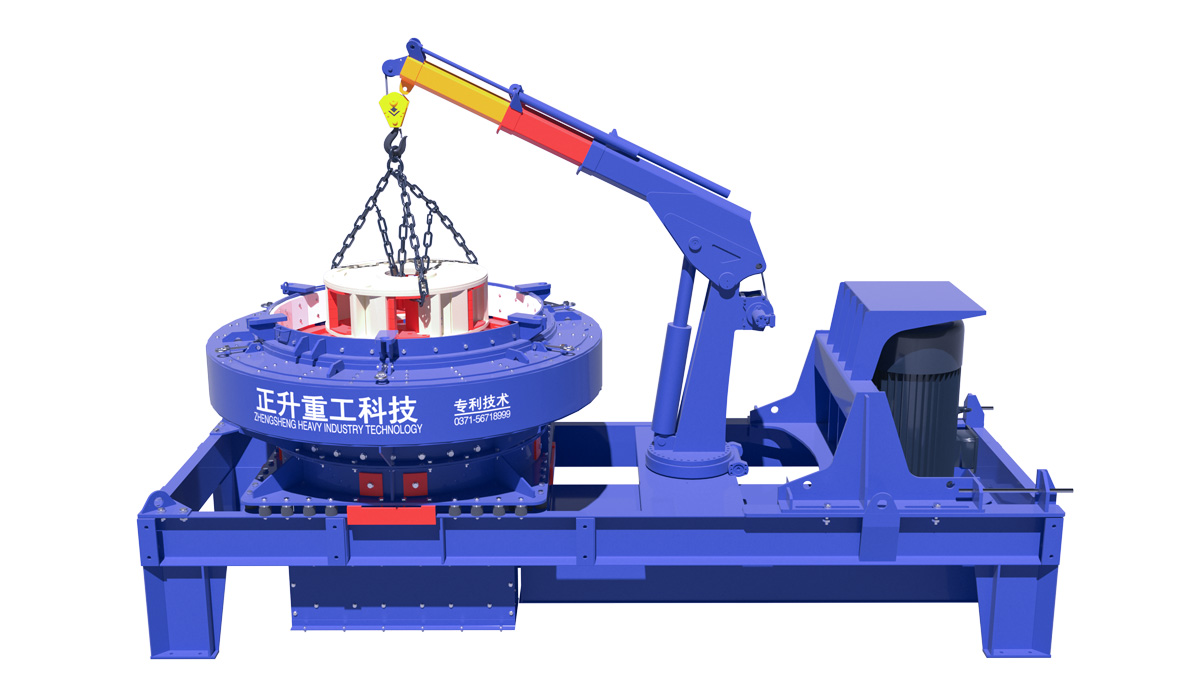

3.Mechanical boom:Maintenance is more time-saving and simple

3.Mechanical boom:

Maintenance is more time-saving and simple

The machine is equipped with a mechanical boom, which can realize the replacement and maintenance of the whole machine, making the maintenance and replacement of vulnerable parts simpler and more mechanized. At the same time, it takes into account the replacement of vulnerable parts such as rotor and annular lining plate, and the modular assembly of motor.

4.Ultra high crushing ratio

4.Ultra high crushing ratio

5.Highly intelligent and automatic

5.Highly intelligent and automatic

Users can choose to configure thin oil lubrication system and PLC automatic control and monitoring system according to their own needs. It can monitor the feeding amount, current, oil temperature, spindle temperature, vibration protection and other functions in real time. In addition, we have equipped the centralized control system with two operation modes: remote control and manual operation, which makes the equipment operation and start more flexible and simple.

6.Optional vulnerable parts to ensure production efficiency

6.Optional vulnerable parts to ensure production efficiency

According to the properties of different raw materials, the materials of vulnerable parts can be selected. We will provide users with two sets of configuration schemes of vulnerable parts with high manganese and high chromium according to different working conditions. Users can choose according to the raw materials so as to improve the production efficiency of the production line. We will also recommend the best configuration scheme according to your actual working conditions.

Product Parameter

Product Parameter

|

TYP |

INPUT SIZE (MM) |

Speed (R/Min) |

Sand forming rate |

Capacity (TPH) |

Power(KW) |

|

|

ZSDI-200 |

≤68 |

70 |

50-65% |

40-160 |

90-200 |

|

|

ZSDI-450 |

≤80 |

70 |

50-65% |

160-350 |

200-450 |

|

1. The tire type ship frame structure is adopted, with mobility, high vehicle chassis, small turning radius, and equipped with traction steering shaft, which can realize free transfer work.

2. Oil and electricity dual-purpose design, diesel generator set can be configured to meet the needs of different customers and different working environments.

3. The ship steel frame structure is adopted to make the stress points of the mobile crushing station more uniform, ensure the stability of the continuous operation of the mobile sand making crushing station, and avoid the risk of overturning or falling apart during the operation of the mobile sand making crushing station.

4. The design of hydraulic support makes the mobile crushing station more reasonable. The frame not only increases the stability of the mobile station, but also greatly improves the smoothness of equipment use.

5. It can realize from single application to multiple on-line applications. Through combination and orderly layout, the overall space layout is more reasonable and compact, the working space is saved, the problems such as too long and too wide production line are avoided, and the different production needs of customers are met.

|

Model |

Sand making crusher |

Vibration screening |

Belt Conveyor |

Iron remover |

INPUT SIZE (MM) |

Capacity(T/H) |

Total Power(KW) |

|

ZSLY-ZS1624-Y1860-3 |

ZS1624 |

3YK1860 Or 2YK1860 |

B800 |

Optional |

≤100 |

40-120 |

206.5 |

|

ZSLY-ZS2028-Y2460-3 |

ZS2028 |

3YK246 Or 2YK2460 |

B1000 |

Optional |

100-380 |

467 |