-

Mobile /Portable Combined Crusher Plant (Tire)

This model is customized for customers. According to the specific output, site factors and other comprehensive conditions required by customers, it designs and produces a complete and movable crushing and screening production line integrating feeding system, crushing system and screening system for users.

explore

-

Mobile/Portable Screening Plant(Tire)

The portable screening plant integrates the feeding system, screening system and discharge conveying system. Through optimization, it has excellent operation functions such as construction waste screening, aggregate production and open-pit mining. The equipment can be perfectly combined with other mobile equipment to form a complete crushing and screening production line, which can meet the needs of different working conditions.

explore

-

ZS high efficiency centrifugal impactive sand making machine

● Energy consumption dropping 36.5%

● 20,148,000 kwh of electricity can be saved per year

● More than double feed particle size compared with traditional VSI

● More than double sand forming rate compared with traditional VSI

● Highly automatic and intelligent

● Shaping and sand making integrated machine

● Double cavity structure, non clogging production

● Thin oil lubrication, various automatic protection measures to reduce fault shutdown time

explore

-

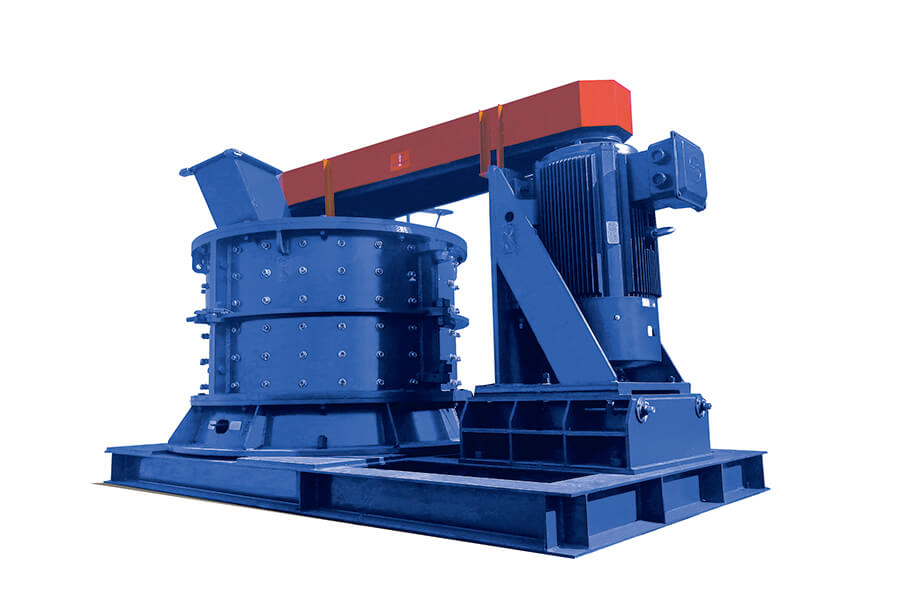

ZSL Series Compound sand making machine

● If your raw material is all soft rock, choose it

● Using the principle of stone striking stone, the wear is small and the service life of vulnerable parts is long

● BIGGER INPUT SIZE ≦ 100-240MM

● After crushing, 70 – 85% of the materials below 3mm can be reached

● Applicable to small and medium-sized investors

● Stable rotation, low noise, low vibration and good sealing. The utility model has the advantages of convenient operation, small floor area, convenient installation and maintenance.

explore

Contact Us Now

Submitting your email address can ensure that you receive our latest consultation as soon as possible!

Inquiry now

*We will not share your personal information

Inquiry now

*We will not share your personal information