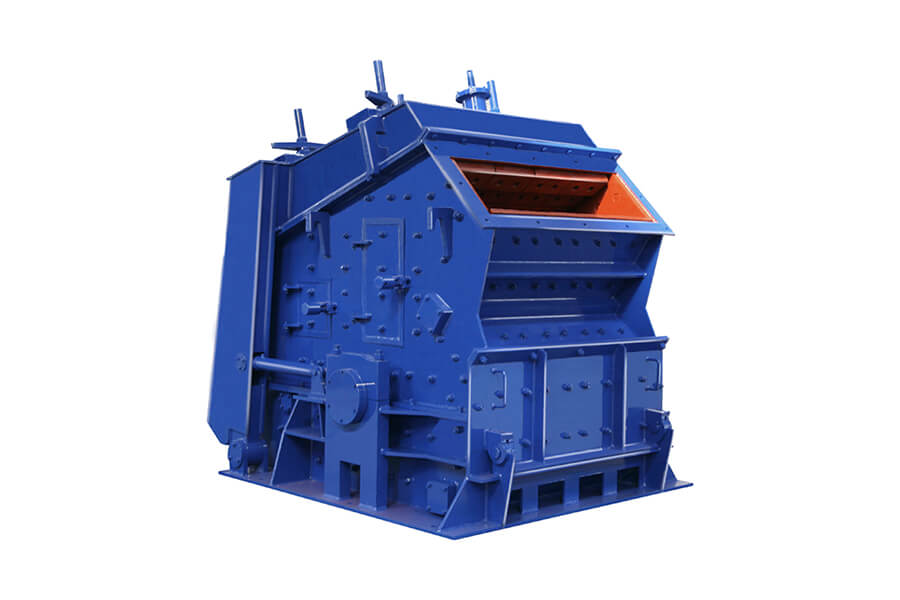

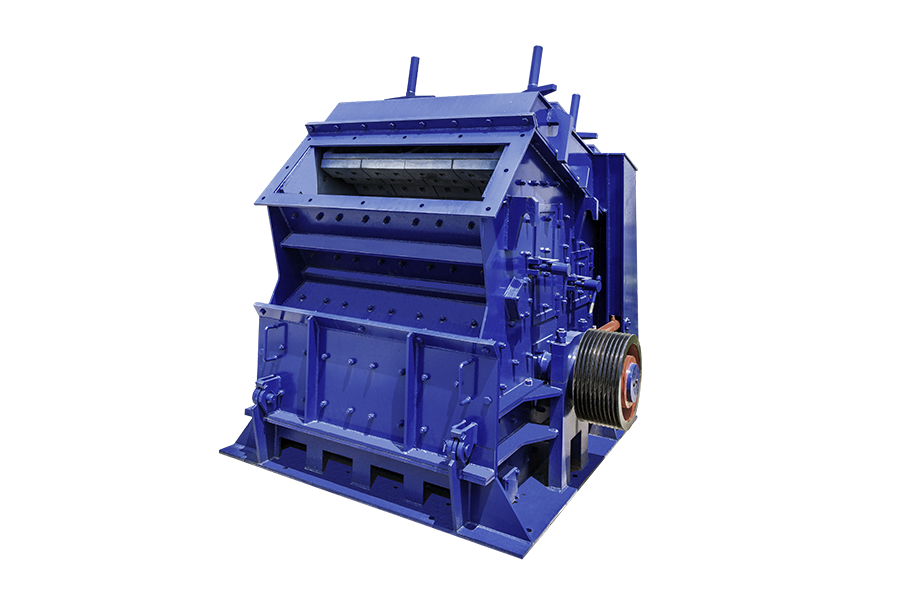

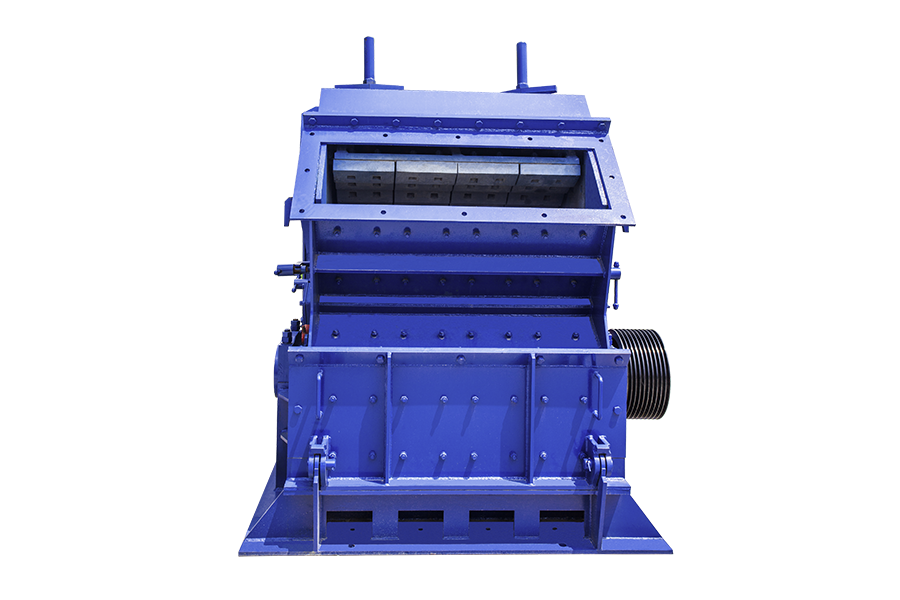

PFW European Imapct Crusher

PFW European impact crusher is a high-performance crusher launched by our company, which is an innovation in the crushing field! It is characterized by small volume, cubic finished product, simple structure, low energy consumption, large production capacity, uniform product particle size, large feed particle size up to 1000mm and large crushing ratio, which solves the objective defects of small feed and low production capacity.

Advantages

1. Special cavity and large feed port design make the feed size larger, so that the equipment has a larger crushing ratio. The flexible adjustment of the gap between the impact plate and the discharge port can not only ensure the crushing efficiency of the equipment, but also ensure that the particle shape of the finished product is more round

2. The heavy rotor design is adopted for finite element structural stress analysis, which has greater rotational inertia on the basis of ensuring its stability, so as to improve the crushing efficiency of the equipment

3. The spring safety device can automatically adjust the gap between the impact plate and the discharge port to release foreign matters if foreign matters (such as iron block and shovel teeth of forklift) enter the crushing chamber during crushing production. So as to avoid the machine jamming and save downtime.

Principle

PFW Series European Vesion Of High-Efficiency Imapct Crusher is a crushing machine which using the impact energy to crush material.When working,the rotor high-speed rotates and the materials is put in the part of impact energy effects,where there are plate hammers in the rotor.The materials are impacted back to the lining plate of impacting devices and then back to the hammer again.Materials are repeated broken from big to smal,which a two or three back cavity,until the material being broken to the required size,and finally mixed materials are being exhausted from port discharge.Adjusting the clearance between the back frame and rotor can achieve the purpose of the material discharging granularity and material shape.

Product Parameter

|

Model |

Rotor (mm) |

Feed opening(MM) |

Max. feed size(MM) |

Capacity (T/H) |

Power (KW) |

Dimension (mm) |

|

PFW-1214III |

Ø1250x1400 |

570x1430 |

250 |

90-190 |

132 |

2850x2400x2900 |

|

PFW-1315III |

Ø1320x1500 |

625x1530 |

300 |

150-280 |

250 |

3100x2800x3160 |

|

PFW-1318III |

Ø1320x1500 |

625x1830 |

300 |

220-350 |

250 |

3100x3210x2613 |

|

PFW-1320III |

Ø1320x2000 |

860x1530 |

350 |

280-400 |

315 |

3320x3218x2613 |

|

PFW-1520III |

Ø1512x2000 |

1315x2040 |

700 |

350-450 |

400 |

4138x3422x3649 |

|

PFW-1620III |

Ø1612x2000 |

1315x2040 |

700 |

400-600 |

450 |

4236x3572x3735 |

|

PFW-1820III |

Ø1800x2000 |

1620x2040 |

700 |

550-800 |

630 |

4471x3250x4008 |

|

PFW-1214II |

Ø1250x1400 |

1100x1430 |

500 |

130-220 |

132 |

2850x2400x2900 |

|

PFW-1315S |

Ø1320x1500 |

1200x1520 |

600 |

180-320 |

200 |

3100x2800x3160 |

1. Special cavity and large feed port design make the feed size larger, so that the equipment has a larger crushing ratio. The flexible adjustment of the gap between the impact plate and the discharge port can not only ensure the crushing efficiency of the equipment, but also ensure that the particle shape of the finished product is more round

2. The heavy rotor design is adopted for finite element structural stress analysis, which has greater rotational inertia on the basis of ensuring its stability, so as to improve the crushing efficiency of the equipment

3. The spring safety device can automatically adjust the gap between the impact plate and the discharge port to release foreign matters if foreign matters (such as iron block and shovel teeth of forklift) enter the crushing chamber during crushing production. So as to avoid the machine jamming and save downtime.

PFW Series European Vesion Of High-Efficiency Imapct Crusher is a crushing machine which using the impact energy to crush material.When working,the rotor high-speed rotates and the materials is put in the part of impact energy effects,where there are plate hammers in the rotor.The materials are impacted back to the lining plate of impacting devices and then back to the hammer again.Materials are repeated broken from big to smal,which a two or three back cavity,until the material being broken to the required size,and finally mixed materials are being exhausted from port discharge.Adjusting the clearance between the back frame and rotor can achieve the purpose of the material discharging granularity and material shape.

|

Model |

Rotor (mm) |

Feed opening(MM) |

Max. feed size(MM) |

Capacity (T/H) |

Power (KW) |

Dimension (mm) |

|

PFW-1214III |

Ø1250×1400 |

570×1430 |

250 |

90-190 |

132 |

2850x2400x2900 |

|

PFW-1315III |

Ø1320×1500 |

625×1530 |

300 |

150-280 |

250 |

3100x2800x3160 |

|

PFW-1318III |

Ø1320×1500 |

625×1830 |

300 |

220-350 |

250 |

3100x3210x2613 |

|

PFW-1320III |

Ø1320×2000 |

860×1530 |

350 |

280-400 |

315 |

3320x3218x2613 |

|

PFW-1520III |

Ø1512×2000 |

1315×2040 |

700 |

350-450 |

400 |

4138x3422x3649 |

|

PFW-1620III |

Ø1612×2000 |

1315×2040 |

700 |

400-600 |

450 |

4236x3572x3735 |

|

PFW-1820III |

Ø1800×2000 |

1620×2040 |

700 |

550-800 |

630 |

4471x3250x4008 |

|

PFW-1214II |

Ø1250×1400 |

1100×1430 |

500 |

130-220 |

132 |

2850x2400x2900 |

|

PFW-1315S |

Ø1320×1500 |

1200×1520 |

600 |

180-320 |

200 |

3100x2800x3160 |