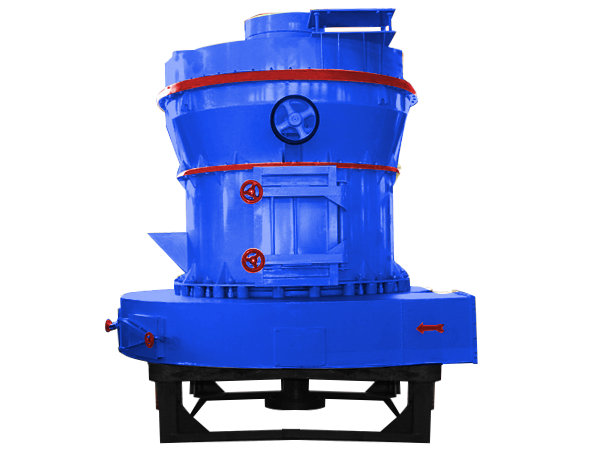

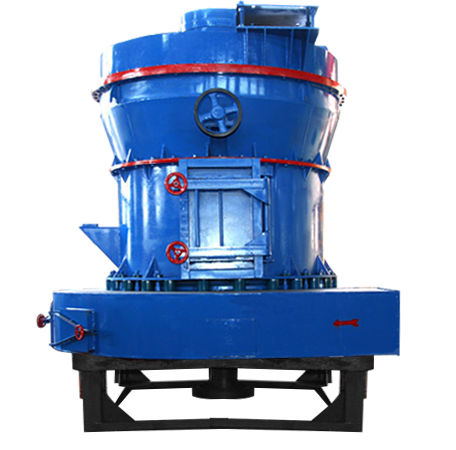

Raymond Mill

The Raymond mill or the Raymond grinder is a kind of grinding plant used widely to grind materials in the industries of metallurgy, construction materials, chemical engineering and mining. Raymond mill can process the non-flammable and non-explosive materials with the mohs hardness of smaller than seventh grade and the humidity less than 6% such as the gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, iron oxide, iron ore etc. The fineness of the finished products is between the 0.613mm-0.44mm range. By working with the analytical machine and the fan, the Raymond mill can meet different requirements from customers.

Product Superiority

1. low operation cost

The material is directly rolled and grinded on the grinding plate by the grinding roller, and the energy consumption is low; Since the grinding roller does not directly contact with the grinding disc during operation, and the grinding roller and lining plate are made of high-quality materials, the wear is less and the service life is long.

2. simple and reliable operation

The automatic control system can realize remote control and is easy to operate; It is equipped with a device to prevent direct contact between the roll sleeve and the lining plate of the grinding plate, so as to avoid destructive impact and violent vibration; It is more convenient to replace the roll sleeve and lining plate by overhauling the oil cylinder to turn over the boom and reduce the shutdown loss.

3. energy saving and environmental protection

The vibration is small, the noise is low, and the equipment is sealed as a whole. The system works without negative pressure, and there is no dust overflow.

Working Principle

Firstly, raw material is crushed by jaw crusher to the size required, then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder, evenly and continuously into the grinding chamber for powder-processing. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

After this, the ground stuff are carried by the air from the blower into the separator for screening. The fine powers are blow into the cyclone collector and are poured out through the output-powder valve as the final products and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Product Parameter

|

Model |

ZS4525 |

ZS4119 |

|

Feeding Size(mm) |

≤30 |

≤25 |

|

Output Size(mm) |

0.173-0.044 |

0.173-0.044 |

|

Shift Output of Different Material Fineness(t) |

16-176 |

8-78 |

|

Rotation Speed of Central Shaft(r/min) |

82 |

105 |

|

Ring Diameter(mm) |

1770 |

1400 |

|

Roller Diameter(mm) |

450 |

410 |

|

Roller Height(mm) |

250 |

190 |

|

Main Motor(kw) |

Y315M-4-132 |

Y280S-4-75 |

|

Fan Motor |

Y315M-4-132 |

Y280S-4-75 |

|

Analyzer Motor |

YCT250-4A-18.5 |

YCT200-4B-7.5 |