GZD/ZSW Series Vibrating feeder

Machine Construction

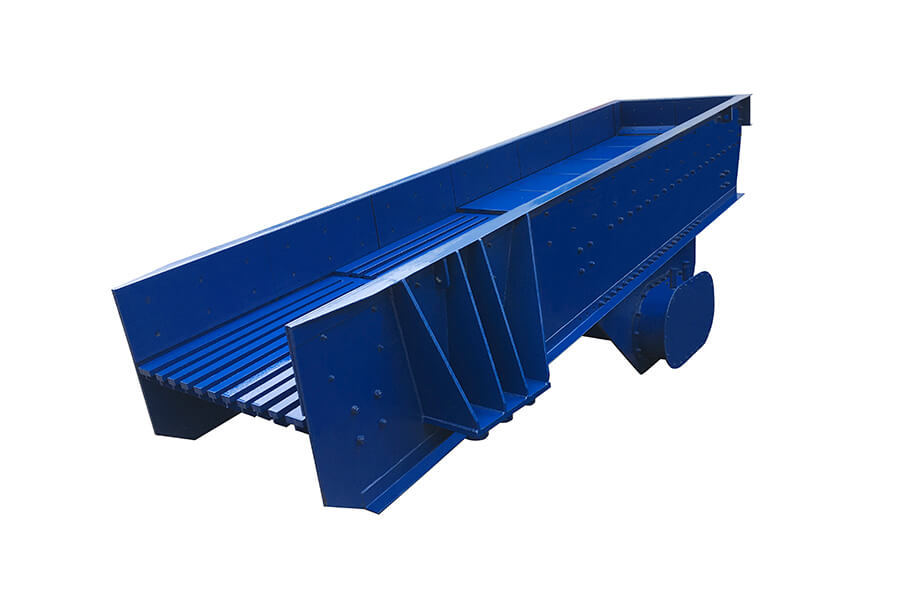

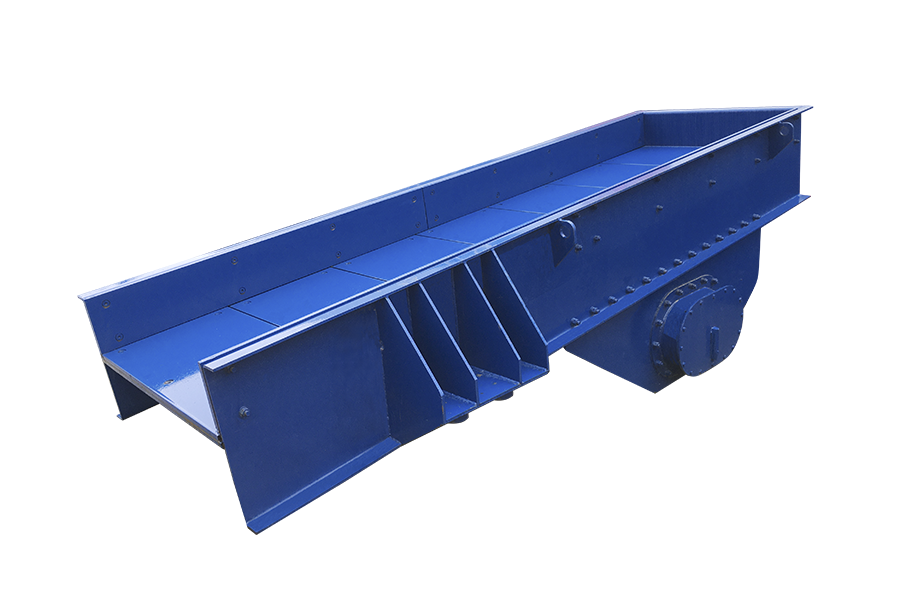

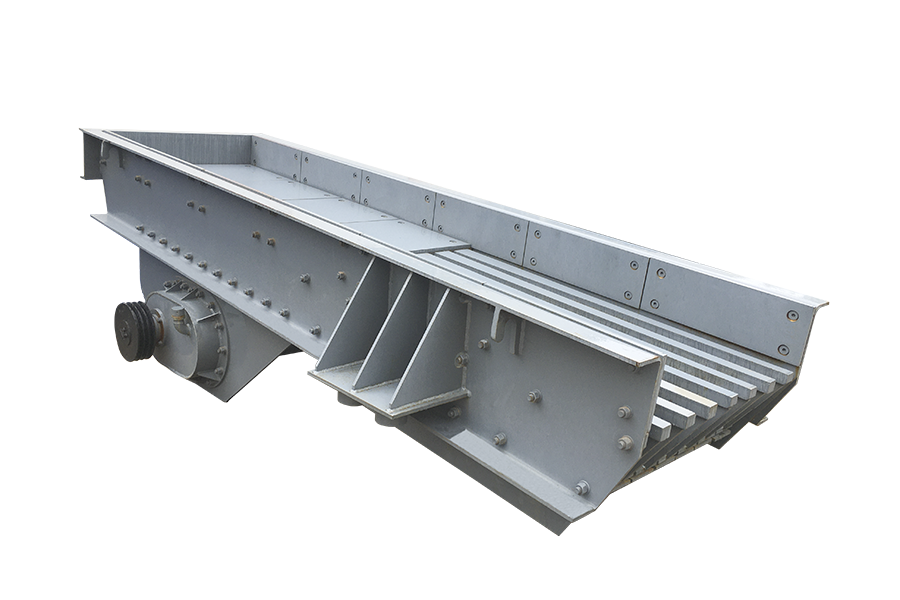

The feeder is composed of frame, spring, exciter, motor, support and other main components.

Working Principle

The vibrating feeder uses the centrifugal force generated by the rotation of two eccentric shafts in the vibrator to make the movable parts such as screen box and vibrator move in a forced continuous circle or approximate circle. The vibration source of tank vibration feeding is the vibration exciter, which is composed of two eccentric shafts and gear pairs. The motor drives the driving shaft through the triangular belt, and then the gears on the driving shaft mesh with the driven shaft to rotate. The driving and driven shafts rotate in the opposite direction, so as to make the tank vibrate and make the materials flow continuously, so as to achieve the purpose of uniform conveying of materials.

The feeder produced by our company has two specifications: flat type and grid section type.

Grid section type has screening function, which can screen out the boring soil and fine particles, making the crusher behind it work more efficiently.

Features

① Stable vibration and reliable operation.

② The grid gap is adjustable.

③ Continuous and uniform feeding.

④ Special grid design, good material fluidity, can prevent material blockage.

⑤ It has the ability of coarse screening to achieve the function of pre screening and increase the output.

⑥ Variable frequency adjustable speed motor can be selected to adjust the frequency, so as to change the output, facilitate the control of feeding amount, and there is no need to start the motor frequently.

⑦ Convenient installation and maintenance.

Product Parameter

|

Model |

Max. feed size (MM) |

Capacity (T/H) |

Pole number |

Power (KW) |

Installation angle(°) |

Groove size(MM) |

Overall dimension (MM) |

|

GDZ 180x80 |

300 |

30-80 |

4 |

2x1.5 |

0-10 |

1800x800 |

1907x964x890 |

|

GDZ 300x90 |

400 |

40-100 |

4 |

2x2.2 |

0-10 |

3000x900 |

3400x1020x900 |

|

ZSW 380x96 |

500 |

120-210 |

6 |

11 |

0-10 |

3800x960 |

3880x1724x1180 |

|

ZSW 420x110 |

650 |

180-400 |

6 |

15 |

0-10 |

4200x1100 |

4200x1804x1180 |

|

ZSW 490x110 |

650 |

250-380 |

6 |

18.5 |

0-10 |

4900x1100 |

4976x1864x1180 |

|

ZSW 490x130 |

800 |

300-550 |

6 |

22 |

0-10 |

4900x1300 |

4976x2064x1180 |

|

ZSW 600x130 |

800 |

340-600 |

6 |

30 |

0-10 |

6000x1300 |

6100x2004x1250 |

|

ZSW 600x160 |

1050 |

400-800 |

6 |

37 |

0-10 |

6000x1600 |

6400x3085x2395 |

|

ZSW 600x200 |

1080 |

500-1000 |

6 |

45 |

0-10 |

6000x2000 |

6400x3485x2395 |

① Stable vibration and reliable operation.

② The grid gap is adjustable.

③ Continuous and uniform feeding.

④ Special grid design, good material fluidity, can prevent material blockage.

⑤ It has the ability of coarse screening to achieve the function of pre screening and increase the output.

⑥ Variable frequency adjustable speed motor can be selected to adjust the frequency, so as to change the output, facilitate the control of feeding amount, and there is no need to start the motor frequently.

⑦ Convenient installation and maintenance.

|

Model |

Max. feed size (MM) |

Capacity (T/H) |

Pole number |

Power (KW) |

Installation angle(°) |

Groove size(MM) |

Overall dimension (MM) |

|

GDZ 180×80 |

300 |

30-80 |

4 |

2×1.5 |

0-10 |

1800×800 |

1907x964x890 |

|

GDZ 300×90 |

400 |

40-100 |

4 |

2×2.2 |

0-10 |

3000×900 |

3400x1020x900 |

|

ZSW 380×96 |

500 |

120-210 |

6 |

11 |

0-10 |

3800×960 |

3880x1724x1180 |

|

ZSW 420×110 |

650 |

180-400 |

6 |

15 |

0-10 |

4200×1100 |

4200x1804x1180 |

|

ZSW 490×110 |

650 |

250-380 |

6 |

18.5 |

0-10 |

4900×1100 |

4976x1864x1180 |

|

ZSW 490×130 |

800 |

300-550 |

6 |

22 |

0-10 |

4900×1300 |

4976x2064x1180 |

|

ZSW 600×130 |

800 |

340-600 |

6 |

30 |

0-10 |

6000×1300 |

6100x2004x1250 |

|

ZSW 600×160 |

1050 |

400-800 |

6 |

37 |

0-10 |

6000×1600 |

6400x3085x2395 |

|

ZSW 600×200 |

1080 |

500-1000 |

6 |

45 |

0-10 |

6000×2000 |

6400x3485x2395 |